Verification and Validation (V&V) are procedures used to check the accuracy and credibility of simulation models.

Verification is a process that determines if the model is predicting accurate outcomes based on the relationships of input variables and output variables that are built into the model.

Validation is a process that reviews the accuracy of the model’s representation of the real-world product or system.

RAMDO V&V Key Features

RAMDO V&V allows engineers to validate their simulation models — even with limited input and output test data — by generating Target Output distributions. To handle limited data, RAMDO provides two quantitative validation measures: Error Range and Confidence Level.

The Target Output distributions are very good approximations of true output distributions. They can only be obtained when large numbers of output test data, which are very expensive, are used. The Target Output distributions provide benchmarks for validation of the simulation model. The quantitative validation measures provide simulation engineers with advantageous information to further improve their simulation model. RAMDO’s proprietary technologies of Dynamic Kriging™ and Variance Window™ are used in obtaining the Error Ranges and Confidence Levels.

In addition, RAMDO provides confidence-based assessments of product reliability even when the simulation model is biased and input and output data are limited.

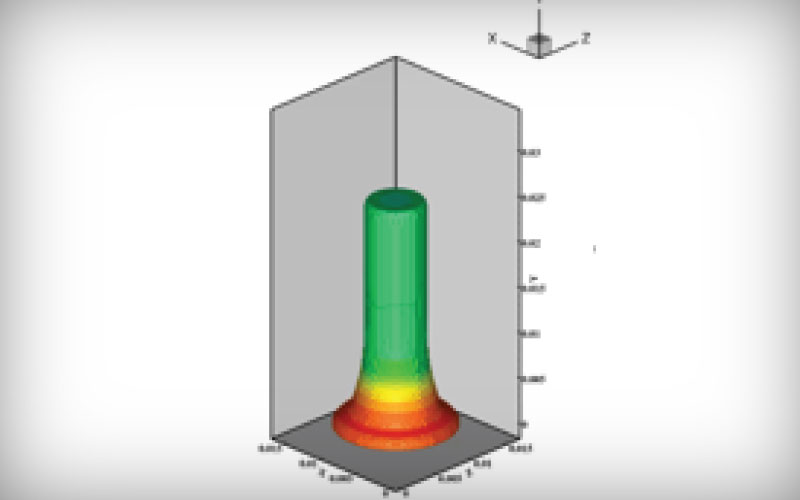

RAMDO V&V was used in conjunction with SCIMITAR3D to predict mushroom diameter and bar length for a Taylor bar impact problem. Input variables for the simulation included: yield stress, strain hardening constant, and strain hardening exponent. The previous approach to validate this simulation performed a point-wise comparison, which ignored the variability of the input variables. RAMDO’s V&V included analyzing input variability and performing a model validation that helped engineers confidently compare simulation data with test data.

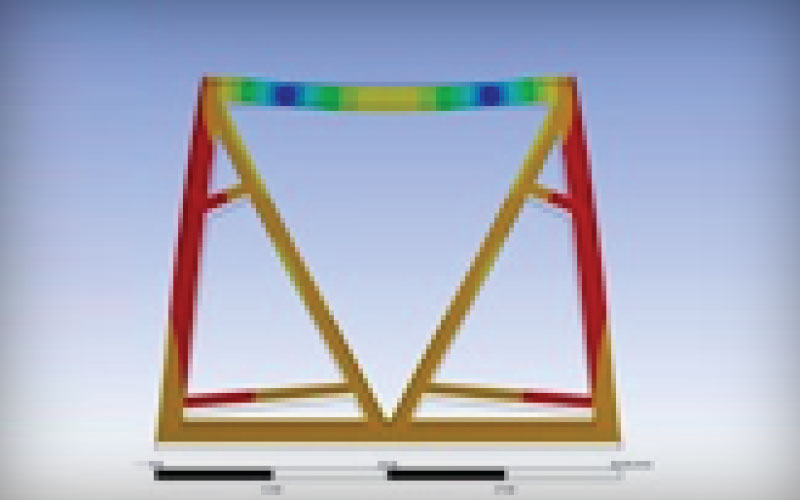

RAMDO V&V was used in conjunction with ANSYS topology optimization to analyze an offshore platform panel structure design. The previous approach used only three simulations and three experimental data points to validate the model, leaving engineers with an unknown level of accuracy and confidence in the model’s predictions. When RAMDO’s V&V was applied, engineers were able to produce a statistical comparison between simulation output and test data and provide a confidence-based error level.

Applications of RAMDO V&V

Validation of simulation model

Statistical comparison between test data and simulation model

Best representative distribution that fits the test data

Model error quantification

Calibration of simulation model